Glass Types

Clear Glass

Clear glass has the same process as the Float glass with just adding Silica Sand, Soda, Lime, Potash and Alkaline Salts. Clear Glass is colourless with visible light transmittance. The visibility of the clear glass varies slightly depending on the thickness of the glass. For example 3mm thick glass has visibility of 88% and visibility of light in 15mm thick glass transmits 79%.

Float Glass

The familiar jagged edge pattern with lethal slithers of glass which, depending on the strength of impact, either fly out or remain precariously intact. Often the removal of shattered pieces are difficult and dangerous.

Laminated Safety Glass

A web-like pattern is the result of a bonded vinyl interlayer holding two sheets of broken laminated glass basically intact. With this tendency to “give” and not fall out under impact, the severity of physical injury is decidedly lessened. Broken laminate safety window glass will remain intact as a barrier against the weather while visibility is partially retained. Grade A laminate safety glass can be used anywhere there is a risk of human impact.

Rolled Glass

Rolled Glass is a process in which pouring molten glass in between rollers to produce the thickness of glass required. Australia has two types of rolled glass : patterned and wired.

Toughened Glass

In the event of toughened glass being broken, the particles are small, and are relatively harmless compared with the sharp splinters resulting from the breakage of ordinary glass. Grade A toughened safety glass may be used where the possibility of human impact exists or in any situation requiring strength, safety or resistance to temperature fluctuations.

Wired Safety Glass

When wired safety glass is smashed the glass will remain attached to the wire and the sheet of broken glass basically remain in place and intact. Wired glass is rolled and produced by using a sandwiching like process by pressing a steel wire mesh between two ribbons of glass. The glass is the passed between a pair of consolidating rollers, the rollers are what impresses the pattern into the glass.

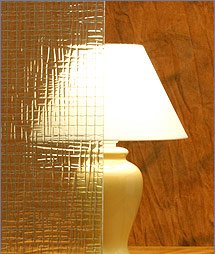

Patterned Glass

Patterned glass is a not-perfectly-smooth structure with different patterns impressed on it. The depth, size and shape of the patterns largely determine the magnitude and direction of reflection. Patterned glass usually transmits only slightly less light than clear glass. It can be used for a variety of applications: interior design and decorations, furniture, windows, street furniture etc.

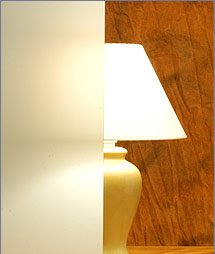

Frosted / Etched Glass

Frosted / Etched glass is produced by acid etching one side of float glass. Acid-etched glass has a distinctive, uniformly smooth and satin-like appearance. Acid-etched glass admits light while providing softening and vision control. It can be used in both residential and commercial settings (doors, shower screens, furniture, wall paneling, etc.)

Tinted / Heat Absorbing Glass

Tinted or Heat Absorbing Glass is also formulated the same way as the float and clear glass process. With just adding small quantities of metal oxides to the normal clear glass to create the desired colour. There are only three colours produced in Australia. The colours consist of green, grey and bronze – Overseas manufactures produce other colours consisting of blue and dark grey. The inclusion of metal oxides creates colour to the glass but has no affect to its basic properties there are exemptions for variation in the amount of solar energy. The visibility of the light will also vary depending the colour of the glass and the thickness.

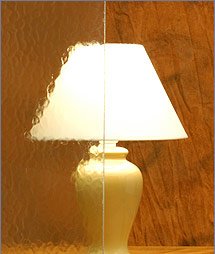

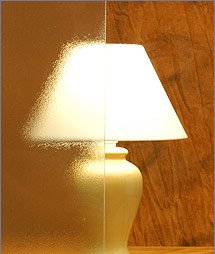

Obscured Glass

A type of glass with one surface roughened in such a way as to reduce visibility but yet allow light to enter a structure. This type of glass is often used in bathroom windows. Also referred to as translucent glass. Some obscure or pattern glass gets its pattern by going through rollers after the float glass process that have the pattern on the rollers.